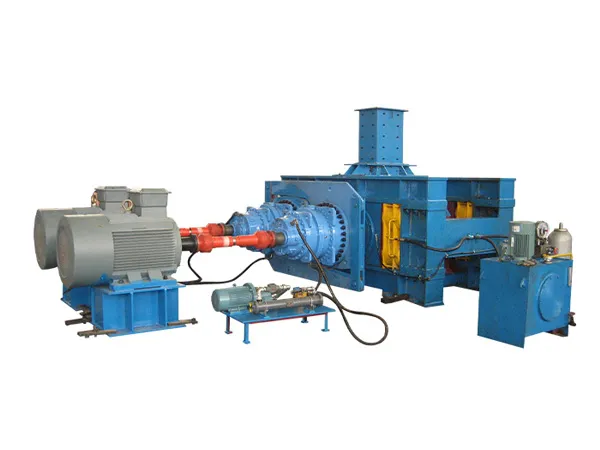

Choosing the right high pressure grinding rolls (HPGR) for your specific needs involves considering several key factors. Here’s a step-by-step guide to help you make an informed decision:

1. Understand Your Requirements

Feed Material: Consider the type, size, and hardness of the material you will be processing.

Capacity: Determine the desired throughput in tons per hour (tph) or specific energy consumption.

Particle Size Requirements: Define the desired final product size distribution.

2. HPGR Configuration:

Single vs. Twin: Decide between single- and twin-roll configurations. Twin-roll HPGRs usually have higher throughput but might require more maintenance.

Drive Systems: Consider fixed speed vs. variable speed drives based on your operational needs and energy efficiency goals.

3. Operating Conditions:

Pressure Settings: Determine the operating pressure range based on the hardness of the material. Higher pressure is often required for harder ores.

Moisture Content: Consider the moisture content of the feed material, as it can affect the performance of the HPGR.

4. Liner Design:

Segment Type: There are different liner segment designs, such as studs and edge blocks. The choice depends on the material being processed and wear characteristics.

Material Composition: Consider the material composition of the liners for durability and wear resistance.

5. Energy Efficiency and Wear Protection:

Wear Protection: Evaluate the wear protection options like hard-facing materials or ceramic inserts to extend the lifespan of the rolls.

Energy Efficiency: Look for advanced control systems and energy-efficient designs to minimize operational costs.

…

For more detailed information on how to choose high pressure grinding rolls, click here: https://www.zymining.com/en/a/news/high-pressure-grinding-rolls-choose.html