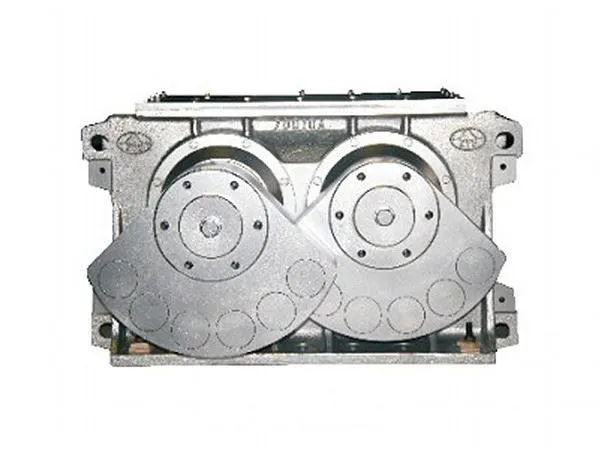

Maintaining a vibrating screen exciter is crucial to ensure the efficient and smooth operation of the vibrating screen. Proper maintenance can extend the life of the equipment and prevent unexpected breakdowns.

Vibrating screen exciter maintenance

Regular Inspections

Visual Inspection: Regularly inspect the exciter and its components for any visible signs of wear, damage, or leaks.

Check Bolts and Fasteners: Ensure all bolts and fasteners are tight and secure. Vibrations can cause them to loosen over time.

Inspect Bearings: Check the condition of the bearings for signs of wear or damage. Ensure they are properly lubricated.

Lubrication

Follow Manufacturer’s Guidelines: Use the type and amount of lubricant specified by the manufacturer.

Regular Lubrication: Regularly lubricate the bearings and other moving parts as per the maintenance schedule.

Check Lubricant Levels: Ensure that lubricant levels are maintained within the recommended range.

Alignment and Balance

Check Alignment: Ensure that the exciter is properly aligned with the vibrating screen.

Balance Exciter: Ensure that the exciter is balanced to avoid uneven vibrations which can cause excessive wear and tear.

Cleaning

Keep Clean: Regularly clean the exciter and surrounding areas to prevent dust and debris build-up.

Check for Blockages: Ensure that there are no blockages in the lubrication passages.

Electrical Components

Inspect Wiring: Regularly inspect all electrical wiring and connections for signs of wear or damage.

Check Insulation: Ensure that the insulation on all wires is intact to prevent short circuits.

…

For more detailed information on vibrating screen exciter maintenance, please click here: https://www.zexciter.com/en/a/news/vibrating-screen-exciter-maintenance.html