Blog

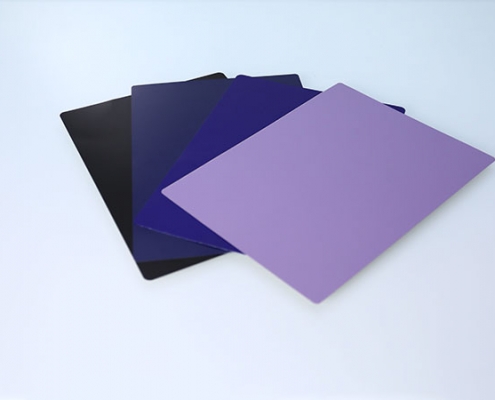

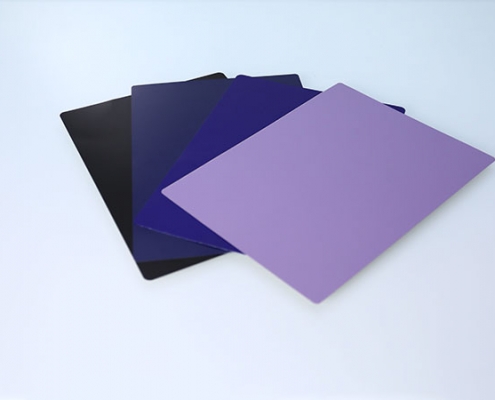

What is the price per square meter of coated aluminum sheet?

NewsThe price of a coated aluminum sheet can vary significantly due to a number of factors. Based on available data, the price per square meter can range from approximately $20 to over $1000 USD depending on the specifications.

Price Range Per…

What is the coating process of coated aluminum sheet

NewsThe coating process of aluminum sheet, also known as coil coating, is a multi-step, continuous process that is highly automated to ensure a uniform and durable finish. The primary goal is to apply a protective and/or decorative layer to the…

What is the speed of precision crossed roller bearings and what are the factors affecting the speed?

NewsPrecision crossed roller bearings are designed for high rigidity, accuracy, and load-carrying capacity in a compact space, not for high speed. Their speed capability is generally considered low to moderate compared to other bearing types like…

What are the accuracy grades for precision crossed roller bearings?

NewsPrecision crossed roller bearings are essential components in applications requiring high rotational accuracy, stiffness, and the ability to handle combined loads (radial, axial, and moment). Their performance is defined by a series of accuracy…

Advantages and Process of Customized Slewing Bearings

NewsCustomized slewing bearings are specifically designed and manufactured to meet the unique requirements of a particular application, rather than using a standard, off-the-shelf product. This approach is common in heavy machinery, renewable energy,…

Installation and Maintenance Guide for Slewing Bearings

NewsSlewing bearings, also known as slewing rings, are crucial components in heavy machinery. They allow for rotational movement while supporting significant axial, radial, and moment loads. Proper installation and maintenance are essential for…