Many people think that there is no difference between a sewage suction truck and a septic tank truck. This is wrong. If you choose the wrong vehicle, it can cause inconvenience after buying the car, spend unnecessary expenses, or even use it, you must be sure before choosing a vehicle It is necessary to figure out your own purpose and use goals, and make clear the purchase of a car. Let me tell you the difference between a septic tank truck and a sewage suction truck.

The septic tank truck and the sewage suction truck have the same principles and are composed of three three principles: the vehicle chassis, the tank body, and the vacuum system. The difference lies in the tank body, so the purpose is greatly different. It can be said that the sewage suction truck can be used as a septic tank truck, but the septic tank truck cannot be used as a sewage suction truck, and it does not have the function of a sewage suction truck. The cost of a septic tank truck is more expensive than a sewage suction truck. Greatly reduce, don’t listen to unscrupulous merchants.

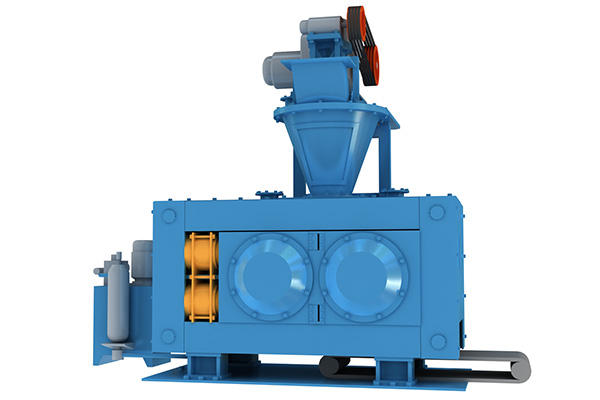

Septic tank truck and sewage suction truck tank distinction

The tank body of the sewage suction truck adopts a round tank body. The advantage of the tank body can be 45 degrees. The tank body can be lifted by a double hydraulic tripod (no residue on the tank body). The back cover of the tank body can be opened at a right angle of 90 degrees. (There is no restriction on the sewage discharge of the tank body. , As long as there is nothing that can be pumped in, it is mainly used for pumping septic tanks, farm feces, sewage sludge and stones, with thicker sediments and objects with more debris.

The tank body of the septic tank truck adopts an oval tank body. The tank body is integrally sealed and has a simple structure. It is mainly used for pumping septic tank feces and sewage (the tank body has limitations, such as stones, bricks, and non-liquid objects. It is difficult to discharge , Difficult to clean up.)

Both cars are equipped with self-extracting and self-draining devices, which are simple to operate and easy to use. Before you buy a vehicle, you must figure out your purpose. Where is the main job used, such as simply pumping a septic tank, buy a septic tank truck. If the job is diversified, be sure to buy a sewage suction truck to avoid future troubles.