The relaxation screen and vibrating screen are both used in various industries to process materials, but they operate based on different principles and serve different functions.

Difference between relaxation screen and vibrating screen

1. Operation Principle:

Relaxation Screen:

A relaxation screen typically refers to a type of screen where the material being processed is allowed to settle or “relax” as it moves across the screen surface. This allows the particles to find natural gaps and fall through the mesh more easily.

It usually relies on gravity and controlled movement of the material, allowing fine particles to pass through openings without significant agitation.

This method is more suitable for delicate or fragile materials that might be damaged by vigorous motion.

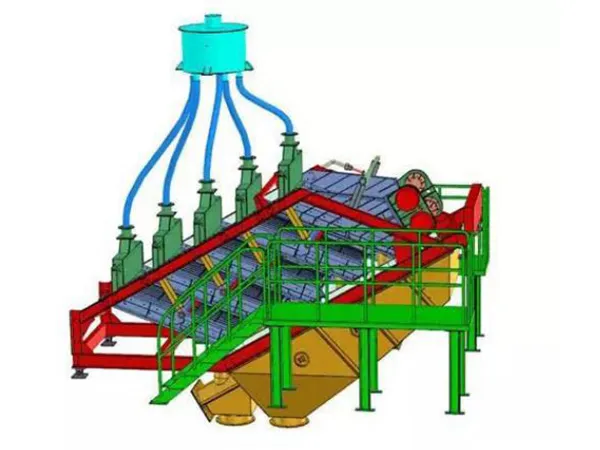

Vibrating Screen:

A vibrating screen works by using a motor to create vibrations that agitate the material being screened. The entire screen surface vibrates, causing the material to move in a specific direction.

The constant vibration helps in separating particles of different sizes more efficiently. Vibrating screens are usually more aggressive and are designed to process large volumes of material in shorter periods.

They come in various types, such as circular, linear, or elliptical motion, depending on the vibrating mechanism used.

2. Intensity of Motion:

Relaxation Screen:

Has gentle movement, which allows materials to settle and find natural spaces through which they can pass. There is little to no agitation, relying more on the material’s flow across the screen.

Suitable for fine or delicate materials that need less forceful handling.

Vibrating Screen:

The screen surface experiences vigorous, repeated vibrations, which force the material to move across the screen in a controlled manner. The motion helps separate fine and coarse materials quickly.

Ideal for heavy-duty applications, such as mining, construction, and bulk material processing.

3. Application and Materials Processed:

Relaxation Screen:

Often used for fine screening and materials that are sensitive to damage or breakage. Examples include processing fragile particles, powders, or granular substances.

Can be used in food processing, chemical industries, or any application where gentle handling is essential.

…

For more detailed information about the difference between relaxation screen and vibrating screen, please click to visit: https://www.zexciter.com/en/a/news/difference-between-relaxation-screen-and-vibrating-screen.html