A tractor clutch kit typically refers to a set of components that includes the clutch disc, pressure plate, release bearing, and sometimes an alignment tool. These components are essential parts of a tractor’s clutch system, allowing the tractor to engage and disengage the engine from the transmission. When the clutch pedal is depressed, it disengages the clutch, allowing the tractor to change gears or come to a stop without turning off the engine.

The components in a tractor clutch kit

1. Clutch Disc

The clutch disc is the main component that engages with the flywheel and the pressure plate. It contains friction material on both sides and is squeezed between the pressure plate and the flywheel to transmit power from the engine to the transmission.

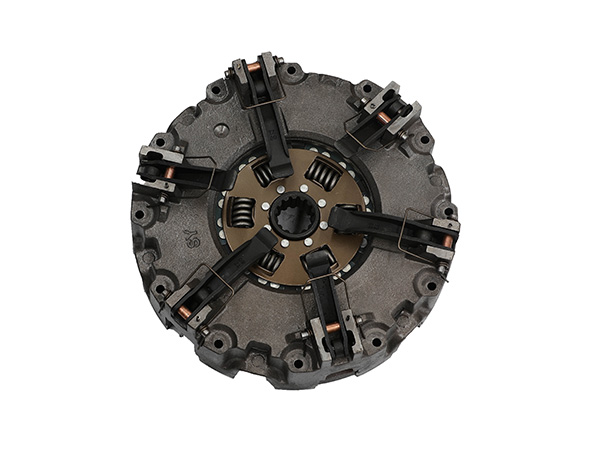

2. Pressure Plate:

The pressure plate is a heavy metal plate that, when engaged, presses the clutch disc against the flywheel. This pressure allows power to be transferred from the engine to the transmission. When you release the clutch pedal, the pressure plate disengages, allowing the engine and transmission to spin independently.

3. Release Bearing (Throw-Out Bearing):

The release bearing is a bearing encased in a collar. When you press the clutch pedal, the release bearing moves toward the pressure plate, releasing the pressure on the clutch disc and disengaging the clutch. It’s a critical component for smooth clutch operation.

4. Alignment Tool:

Some clutch kits come with an alignment tool. This tool helps in aligning the clutch disc properly during installation, ensuring that the transmission input shaft fits smoothly through the center hole of the clutch disc.

Important Considerations

Compatibility: Ensure that the clutch kit you choose is compatible with the specific make and model of your tractor. Tractor models can vary widely, so it’s important to get the right parts for your tractor.

…

For more detailed information about the components of the tractor clutch kit, please click here: https://www.syclutch.com/news/tractor-clutch-kit-components.html