Tunnel lining trolleys, also known as tunnel formwork systems or tunnel shuttering machines, are essential equipment used for in-situ concrete lining in tunnel construction. Depending on tunnel structure, size, and construction methods, tunnel lining trolleys can be classified into several types. These are large, mobile structures used inside tunnels to support the formwork for cast-in-place concrete linings or to install precast concrete segments.

Tunnel Lining Trolley Type

The primary categorization is based on the type of lining they are designed for:

Formwork Trolleys (for Cast-in-Place Concrete Lining):

These trolleys carry large sections of steel formwork. They position the formwork against the excavated tunnel profile, concrete is pumped behind it, and once the concrete cures sufficiently, the trolley lowers (strips) the formwork and moves forward (travels) to the next section.

Sub-types based on Formwork Configuration:

Full-Round Formwork Trolley: Carries formwork for the entire tunnel cross-section (invert, walls, and arch) allowing for a single pour. Complex and heavy, often used for circular or near-circular tunnels.

Arch (or Crown/Sidewall) Formwork Trolley: Carries formwork only for the upper arch and sidewall sections. This is used when the invert (floor) is cast separately first (often using simpler screeding or a dedicated invert form). This is very common for horseshoe or D-shaped tunnels.

Invert Formwork Trolley: Specifically designed to carry the formwork for casting the tunnel floor (invert). Often used in conjunction with an Arch Formwork Trolley.

Telescopic Formwork Trolley: The formwork sections are designed to retract inwards (like a telescope) after stripping. This allows the entire trolley to move forward through the previously cast lining section without needing extensive dismantling. This is the most common type for longer tunnels due to efficiency.

Non-Telescopic (Collapsible) Formwork Trolley: Sections may hinge or collapse, but might not fully telescope. Movement might require more clearance or partial dismantling. Less common for continuous tunnel drives.

Portal Formwork: While not strictly a “trolley” in the travelling sense, specialized formwork systems are used at the tunnel entrances/exits (portals).

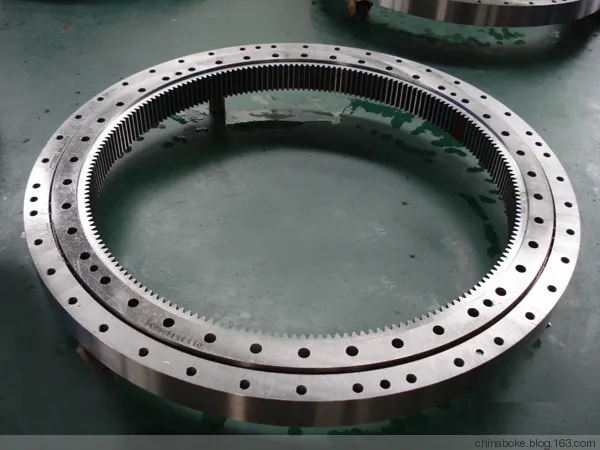

Segment Erector Trolleys (for Precast Concrete Segments):

These are used primarily in tunnels excavated by Tunnel Boring Machines (TBMs), although variations exist for conventional tunnels installing precast linings.

Their main function is to pick up precast concrete segments (delivered usually by multi-service vehicles or segment cars), rotate them to the correct orientation, and precisely place them to form a complete ring against the TBM’s shield or the previously installed ring.

…

More detailed information about tunnel lining trolley types can be found at: https://www.gf-bridge-tunnel.com/a/blog/tunnel-lining-trolleys-type.html