Welding rotators, also known as turning rolls or tank rollers, are essential equipment in the automatic welding of cylindrical workpieces such as tanks, pipes, pressure vessels, and wind towers. Depending on the workpiece size, weight, material, and welding requirements, different types of welding rotators are available on the market. This guide introduces the most common types of welding rotators and their main features.Their primary purpose is to rotate cylindrical workpieces like pipes, tanks, and pressure vessels, allowing welders to maintain a consistent, often downhand, welding position for better quality, efficiency, and safety.

Welding Rotators Types

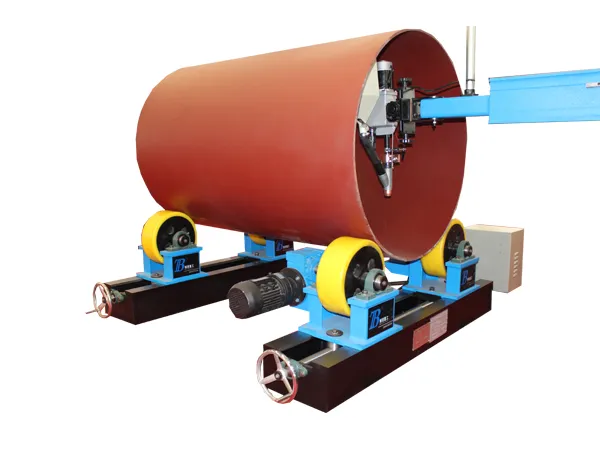

Conventional (or Standard) Turning Rolls:

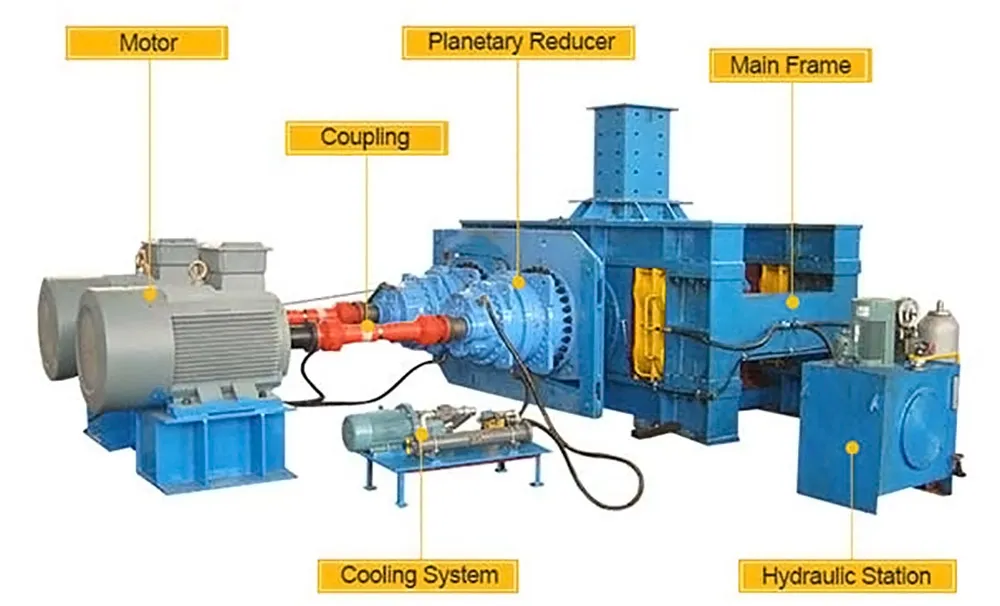

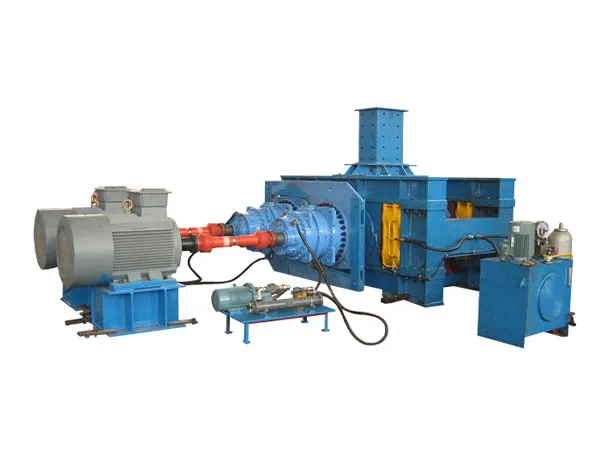

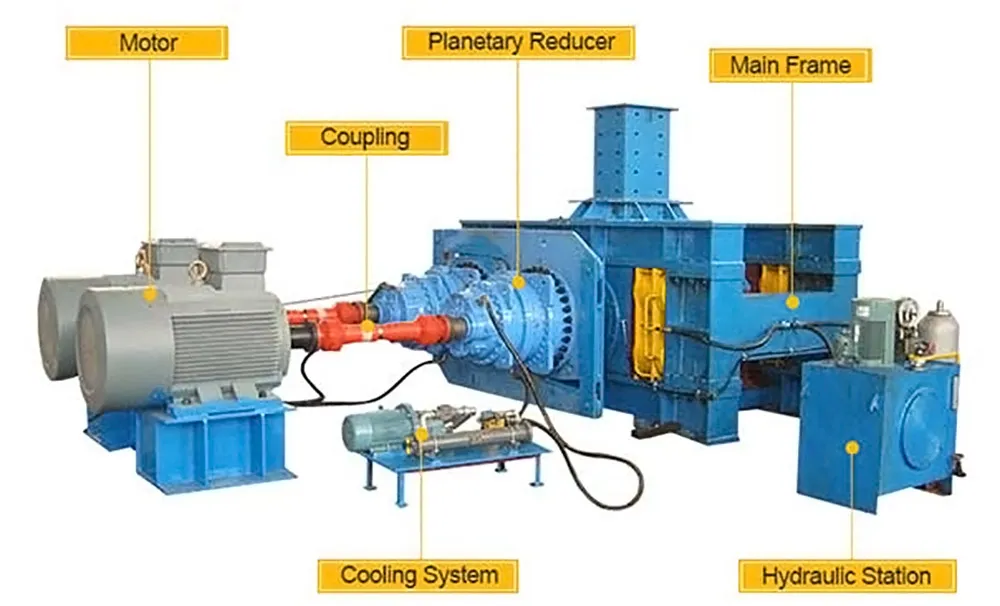

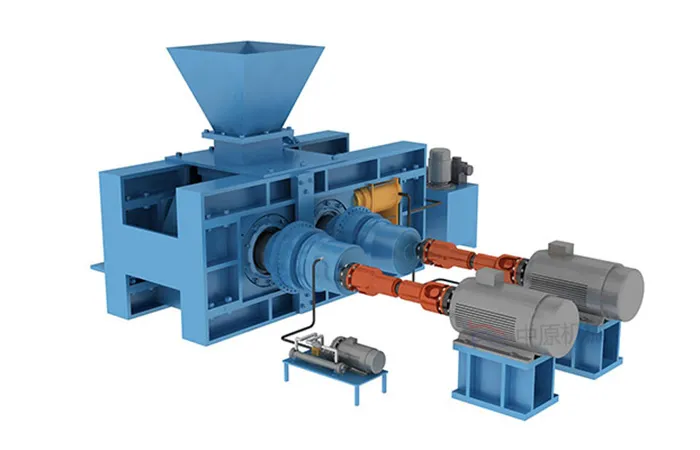

Description: These consist of a powered drive unit and one or more non-powered idler units. Each unit typically has two rollers. The distance between the rollers on each unit is manually adjustable (often via bolts in slots or a leadscrew) to accommodate different workpiece diameters.

How they work: You manually set the roller spacing on both the drive and idler units to match the diameter of the workpiece you intend to weld. The workpiece then rests on these rollers.

Pros: Generally simpler in design, often more cost-effective for a given capacity, robust.

Cons: Requires manual adjustment time when changing workpiece diameters, workpiece needs careful centering, the centerline height of the workpiece may change slightly depending on the diameter and roller setting.

Best Suited For: Shops that frequently work with similar-sized workpieces or where setup time for diameter changes is less critical.

Self-Aligning Rotators (SAR):

Description: These also consist of a drive unit and idler unit(s). However, the key difference is that the roller brackets are designed to pivot or adjust automatically.

As the workpiece is lowered onto the rotator, the rollers swing open or closed to conform to the workpiece’s diameter without manual adjustment of roller spacing.

How they work: The pivoting mechanism ensures that the rollers automatically cradle the workpiece, maintaining multiple contact points. This design often keeps the centerline height of the workpiece relatively constant across a wide range of diameters.

Pros: Significantly faster setup when changing between different workpiece diameters, automatically centers the workpiece to some extent, provides better support (especially for thin-walled vessels) by distributing the load over more contact points, reduces the risk of workpiece marking.

Cons: More complex mechanism, generally more expensive than conventional rotators of the same capacity.

Best Suited For: Fabrication shops dealing with a wide variety of workpiece diameters, applications where quick changeover is important, handling large or thin-walled vessels where good support is crucial.

Other Considerations & Variations (Features often found on both types):

Drive Unit vs. Idler Unit: Rotator sets always include at least one powered “Drive Unit” that provides the rotation and one or more unpowered “Idler Units” that simply support the workpiece. You can add more idler units for longer vessels.

Capacity: Rotators are rated by their weight capacity (e.g., 1 ton, 5 tons, 50 tons, 100+ tons) and the diameter range they can handle.

…

More detailed information about welding rotator types can be found at: https://www.bota-weld.com/en/a/news/welding-rotators-types.html