Tempering furnace convection is an important heating and cooling method in glass tempering furnaces. It mainly transfers heat through the flow of liquid or gas to achieve rapid heating and uniform cooling of glass, thereby improving the strength and durability of glass. The correct use of tempering furnace convection is crucial to ensure the quality and performance of tempered glass.

Tempering furnace convection

1. Tempering furnace convection form

In glass tempering furnaces, there are two main forms of convection: natural convection and forced convection:

Natural convection: Natural convection refers to the phenomenon of spontaneous flow of liquid or gas formed due to temperature difference inside the glass tempering furnace. Hot liquid or gas becomes lighter due to heating and rises to the colder area, while cold liquid or gas sinks to the heated area, forming a circulating flow. This form of convection is relatively common in glass tempering furnaces, especially during the heating and cooling stages. Through natural convection, the temperature distribution on the surface and inside of the glass is more uniform, which helps to reduce the internal stress of the glass and improve the tempering effect.

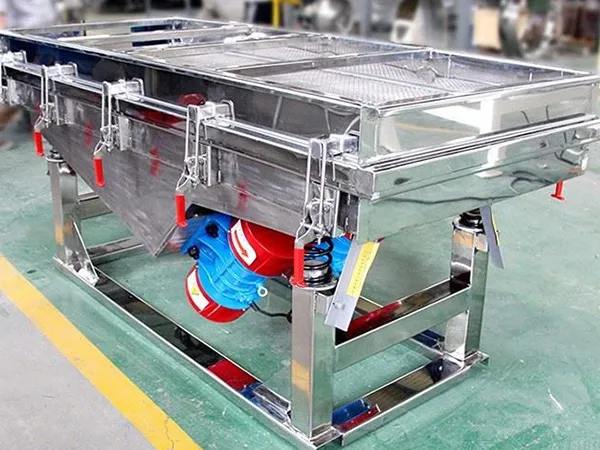

Forced convection: Forced convection is a form of convection achieved by forcing flow through external equipment such as fans, circulating water pumps, etc. In glass tempering furnaces, forced convection is usually used in the heating stage, and the air in the furnace is forced to circulate through the fan, so that the glass is heated more evenly. This helps to reduce temperature differences, improve the heating efficiency of the glass, and ensure that the entire glass surface obtains a uniform temperature distribution. Forced convection also speeds up the cooling process, increasing the strength and impact resistance of the glass.

2. The role of convection in tempering furnaces

Promote uniform temperature distribution: Heating and cooling by convection can make the temperature inside the glass evenly distributed, avoid overheating or local low temperature, and thus ensure the quality and performance of the glass.

Improve heating efficiency: Forced convection can speed up the heating speed of the glass surface, so that the glass can reach the required temperature in a short time, and improve production efficiency.

Enhance the tempering effect: Uniform temperature distribution and rapid cooling process help to create a uniform pressure difference on the surface and inside of the glass, thereby increasing the strength and durability of the glass.

…

For more detailed information on the correct use of tempering furnace convection, please click to visit: https://www.shencglass.com/en/a/news/correct-use-of-convection-tempering-furnace.html