Self-loading garbage truck is a kind of garbage truck that has a very large demand in the sanitation vehicle market in recent years. This model is used in conjunction with plastic square drums or iron drums for the collection and transfer of urban domestic garbage trucks. The hanging bucket garbage truck is small in size, easy to operate, and has the function of self-loading and self-unloading, which greatly reduces the labor intensity of sanitation workers. It is very suitable for use in areas with narrow roads such as residential areas, streets, and rural areas.

Working status of self-loading garbage truck

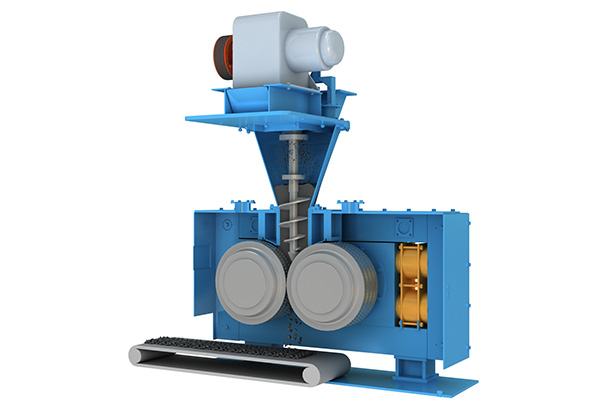

One of the most notable features of the self-loading garbage truck is that the garbage bin full of garbage is lifted by the garbage bin lifting mechanism and automatically dumped into the box of the pull-through garbage truck. Today we will introduce the lifting mechanism of the self-loading garbage truck.

The lifting mechanism of the self-loading garbage truck is mainly composed of hydraulic cylinders, lifting arms, pull rods, lifting frames, turning frames, rockers, rollers and guide rails.

When the self-loading garbage truck needs to load garbage, the control handle of the hydraulic cylinder is moved, the hydraulic system provides power through the hydraulic pump, and the piston rod of the hydraulic cylinder is pushed out, and the lifting arm rotates around the distance between it and the box under the thrust of the piston rod. The hinge point swings, and the lifting arm drives the pull rod to move upwards, and then drives the lifting frame with the trash can to move upwards along the secondary guide rail of the reversing frame until the trash can touches the pressing plate on the reversing frame, and drives the reversing frame to move upwards along the main rail.

When the rollers at the upper end of the turning frame move to the end of the curved track at the top of the main rail, the upper rollers are blocked and stop, and at the same time, the pull rod continues to pull up the lifting frame, so that the axis line of the upper rollers of the turning frame is the turning axis to turn over the trash can until the trash can is finished. Garbage is automatically dumped.

After the garbage is emptied, oil is reversely fed through the double-acting hydraulic cylinder, and the piston rod starts to retract. The lifting arm swings in the opposite direction, so that the garbage can returns to the initial position, and the working process of automatically filling garbage is completed.

Self-loading garbage trucks not only have a wide range of functions, but also have strong scalability. Add a compression push plate to the box of the self-loading garbage truck to become a compressed self-loading garbage truck. Add filter plate in the box, it can be used as a kitchen garbage truck. In addition, we can also add a weighing function to the self-loading garbage truck to detect the amount of garbage collected and so on.

For more details about self-loading garbage trucks, please click to visit: https://www.ly-cimc-linyu.com/sanitation-truck/self-loading-garbage-truck.html

.jpg)