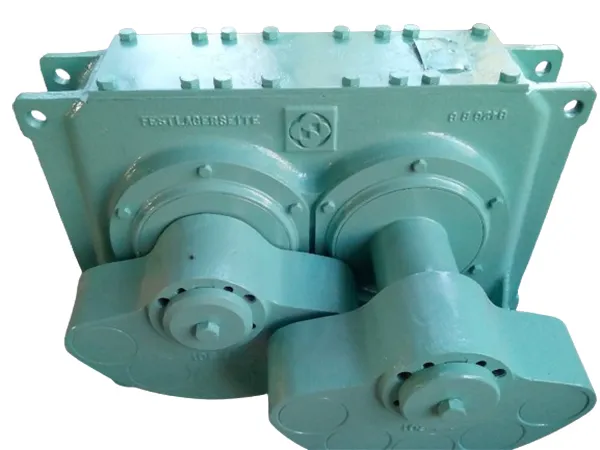

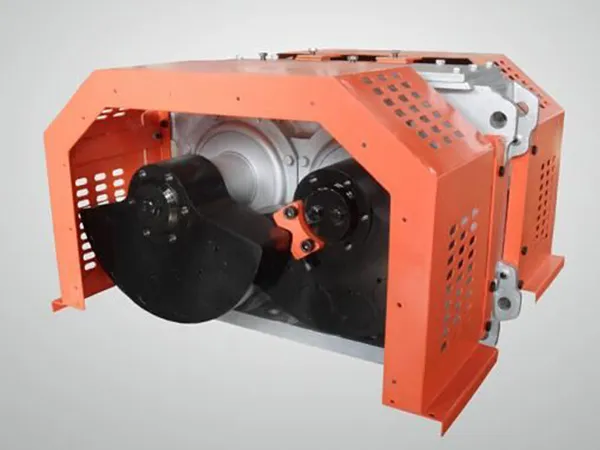

Flange bearings are crucial components in various industrial applications, providing support for rotating shafts while ensuring smooth and efficient movement. Proper lubrication is essential to minimize friction, reduce wear, and extend the bearing’s lifespan. Inadequate lubrication can lead to overheating, premature failure, and increased maintenance costs.Lubricating flange slewing bearings is crucial for their longevity and performance. Here’s a comprehensive guide on how to do it correctly.

Flange Bearing Lubrication

1. Understanding Your Bearing:

Bearing Type: Different types (e.g., single-row ball, double-row ball, roller) have slightly different lubrication needs. Consult the manufacturer’s specifications.

Seal Type: Bearings often have seals to protect the internal components from contamination. The seal design (e.g., contact seals, labyrinth seals) may influence lubrication procedures.

Operating Conditions: Factors like load, speed, temperature, and environment significantly impact lubrication frequency and grease type.

2. Importance of Proper Lubrication:

Reduced Friction and Wear: Lubrication minimizes friction between the rolling elements (balls or rollers) and the raceways, preventing wear and extending bearing life.

Heat Dissipation: Grease helps dissipate heat generated by friction, preventing overheating and potential damage.

Corrosion Protection: Grease acts as a barrier against moisture and contaminants, protecting the bearing from corrosion.

Sealing: Grease contributes to sealing the bearing, keeping contaminants out and lubricant in.

3. Lubrication Materials (Grease):

Choosing the Right Grease: Select a grease specifically designed for slewing bearings and recommended by the bearing manufacturer. Consider these factors:

Base Oil Viscosity: Higher viscosity for heavy loads and slow speeds, lower viscosity for lighter loads and higher speeds. ISO VG 150 to VG 460 are common ranges.

Thickener Type: Lithium complex greases are a popular choice due to their good water resistance, high-temperature performance, and load-carrying capacity.

Calcium sulfonate greases are also excellent for harsh environments.

Additives: EP (Extreme Pressure) additives for high loads, AW (Anti-Wear) additives for general wear protection, and corrosion inhibitors for rust prevention.

Temperature Range: Ensure the grease’s operating temperature range is suitable for your application.

Compatibility: If you’re switching grease types, ensure compatibility with the previous grease to avoid issues. It’s often best to completely clean the bearing when switching greases.

Never Mix Greases of Different Types: Mixing incompatible greases can lead to thickening, hardening, or separation, which can damage the bearing.

4. Lubrication Procedures:

Frequency: This is highly dependent on the operating conditions and the manufacturer’s recommendations. A general guideline is:

Light Duty: Every 100-250 operating hours.

Medium Duty: Every 50-100 operating hours.

…

For more detailed information about flange slewing bearing lubrication, please click here: https://www.mcslewingbearings.com/a/news/flange-bearing-lubrication.html