The concrete floor polishing pad is an upgraded product of the ordinary polishing pad. After molding, there will be no problems such as cracking, chromatic aberration, anti-alkali, etc., it is cast on-site, and the whole is seamless. It is made of negative ion cement mortar, guard armor, guard silk concrete sealing curing agent and jade , Shells, etc., made of pure cement, no TVOC, impermeable, dust-proof, corrosion-resistant, friction-resistant, dense and strong overall, no waxing on the surface, no maintenance, suitable for families, schools, hospitals, factories, workshops, subway stations , Indoor and outdoor use in exhibition halls and other places.

Concrete floor polishing pad use

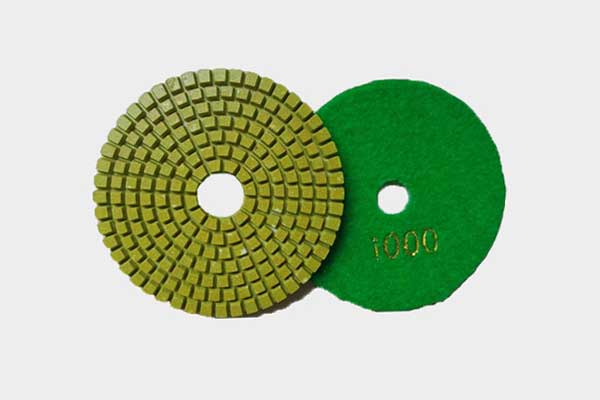

Concrete floor polishing pads are divided into diamond polishing pads, concrete thick polishing pads, concrete thin polishing pads and concrete polishing pads. They are usually installed on refurbishing machines or floor grinders. Different models can be selected according to the supporting machine and the hardness of the floor. Granular polishing pads can be used for ground leveling, rough grinding, fine grinding, fine grinding, polishing, and crystal surface.

Concrete floor polishing pad model

Diamond polishing pad: 30#-50# 50#-100#

Concrete thick polishing pad: 30#-50# 100#-150# 300#-500# 1000#-3000#

Thin concrete polishing pad: 30#-150# 300#-500# 1000#-3000# 2000#-3000#

Concrete thick polishing pad (dry): 30#-50# 100#-150# 300#-500# 1000#-2000#

Thin concrete polishing pad (dry): 30#-150# 300#-500# 1000#-2000# 2000#-3000#

Polishing film: dry polishing 3000# or 6000# 3000# or 6000#

Concrete floor polishing pad construction process

1. Leveling treatment

(1) Removal of the loose surface layer of the old floor: The loose surface layer of the floor can be easily removed by using Yiheng Diamond Grinding Sheet. It is recommended to use a medium and large floor grinder.

(2) Surface treatment of the floor with poor flatness: first level with diamond grinding discs, then rough grinding with thick grinding discs, and then choose suitable concrete thick grinding discs or thin grinding discs for grinding treatment.

(3) Surface treatment of large-area repaired floor: It is recommended to grind and level the ground with a diamond polishing pad before the ground is completely cured, and then use a thick polishing pad to rough-grind and level after the penetration of the sealing curing agent is chemically cured. Ping handling becomes simple and relaxed.

(4) Surface treatment of the old floor with good flatness: Choose a thick abrasive disc with a suitable particle size according to the hardness of the ground, which can make the flatness of the ground better, and the later grinding and polishing process will be faster and better.

2. Coarse grinding treatment

(1) After the ground is leveled, choose a thicker or thinner grinder with a higher particle size for rough grinding. It is recommended to use a medium and large floor grinder.

(2) Terrazzo floor, concrete colored sand floor, and dry-spread hardener floor with uniform exposed sand: Choose coarse and thick grinding discs according to the hardness of the floor. The matching medium and large grinders can improve the grinding efficiency and make the ground smoother it is good.

3. Fine grinding and fine grinding treatment

(1) The newly made aggregate hardener ground maintains the surface effect of the original slurry: it is better to choose a thin concrete grinding plate suitable for fine grinding. A new floor with good mechanical finish is easy to make a uniform surface effect of the puree.

(2) Ground after rough grinding: Choose concrete grinding discs suitable for fine grinding. Both thick and thin grinding discs are applicable. The matching medium and large grinders can improve the grinding efficiency and make the ground smoother.

4. Polishing treatment

Concrete polishing should be carried out after the ground is finely ground or finely ground. The floor should be cleaned and dried before polishing. It is recommended to use a thin abrasive disc for dry polishing. The polishing effect is related to the hardness, flatness and pre-treatment effect of the floor. After dry polishing with a thin polishing pad, polishing with a concrete polishing pad can significantly improve the brightness of the ground.

5. Crystal face treatment

If there is a higher requirement for the brightness of the ground, it is recommended to perform crystal surface treatment after polishing. It is recommended to use concrete brightener for floor crystal surface treatment. After spraying concrete brightener, using 6000# concrete polishing sheet dry polishing, it is easy to bring a lasting and charming mirror effect.

The life of the polishing pad and the polishing effect will be affected by various factors, including the hardness of the ground, the weight of the grinder, the counterweight, the speed, whether to add water and the amount of water, the model, quantity, particle size of the polishing pad, the polishing time and use experience, etc. The concrete floor polishing pad produced by our company can be used with various refurbishing machines and grinders. The thickened concrete polishing pad with medium and large grinders can improve the grinding efficiency and make the ground smoother.