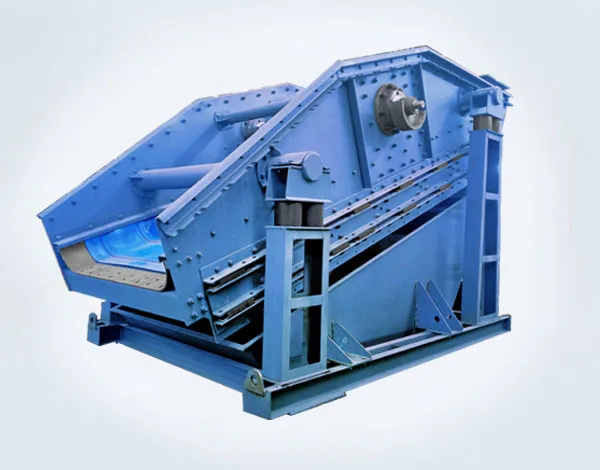

A flip flop screen, also known as a flip flow screen or flip-flop waste separator, is a type of screening machine used in various industries for the separation of materials based on size and composition. It’s particularly useful for handling materials that are difficult to screen using conventional vibrating screens, such as wet, sticky, or highly variable materials.

The design of a flip flop screen typically involves two separate screening decks that are arranged in parallel and connected to a system of cross beams. Each screening deck consists of alternating polyurethane flip flow panels and conventional screening panels. The flip flow panels have a unique design with flexible polyurethane fingers that move independently when subjected to vibration.

The operation of a flip flop screen involves a combination of linear and elliptical vibration, which causes the flip flow panels to flex and relax rapidly. This dynamic motion helps to prevent clogging and blinding of the screen surface, allowing the material to pass through more efficiently. The flexible fingers of the flip flow panels also provide excellent self-cleaning action, further enhancing the screening process.

Flip flop screens features

High Efficiency: Flip flop screens are capable of achieving high screening efficiency, even with difficult-to-screen materials, thanks to their unique design and dynamic motion.

Self-Cleaning: The flexible polyurethane fingers of the flip flow panels help to prevent clogging and blinding of the screen surface, resulting in continuous and uninterrupted operation.

…

For more detailed information about the features of the flip flop screens, please click here: https://www.zexciter.com/en/a/news/flip-flop-screen-features.html