The metal briquetting machine is a professional machine and equipment for forming metal powder materials in many fields such as the metallurgical industry and the energy industry. After the pressed metal powder is molded, it is very convenient and efficient in the use process. It also plays a role in the reuse of metal powder waste and saves resources.

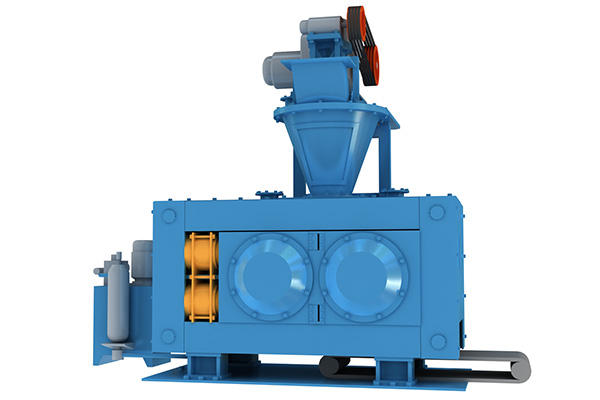

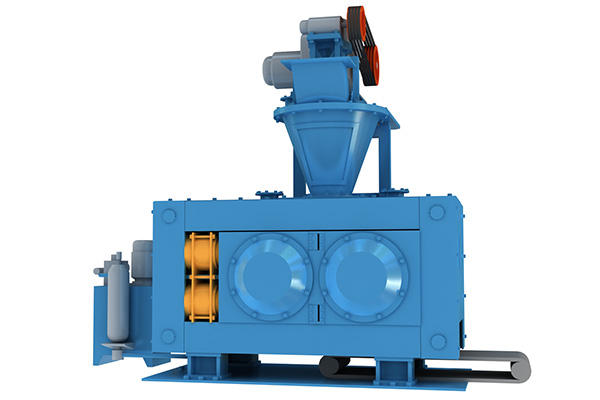

The forming part is the key structure of the metal briquetting machine process. Whether its design is reasonable or not directly affects the forming quality of the metal briquetting machine. The main model of the metal briquetting machine is a pair-roll forming machine (that is, a ball press that people often call). It has a pair of cylindrical wheels with parallel axes, the same diameter, and a certain gap between each other. There are many on the roll skin. With hemispherical sockets of the same shape and size and regular arrangement, the pressing roller is the main part of the metal powder ball press.

The operating principle is: driven by the motor, the two wheels rotate at the same speed and opposite directions. When the material falls between the two pressure rollers, the joint begins to be compressed, and the raw material is produced between the corresponding two ball sockets. Volume compression; the roller continuously rotates, the ball socket is gradually closed, and the molding pressure gradually increases. When the distance between the two ball sockets is the smallest, the molding pressure reaches the maximum. Then the pair of rollers rotate to gradually separate the ball and socket, and the molding pressure decreases rapidly. Before the molding pressure is reduced to zero, the pressed metal powder begins to expand and break away, completing the whole process of pressing by the metal briquetting machine.

Performance characteristics:

1. After years of industrial use and improvement, the metal briquetting machine has obvious advantages such as high ball formation rate, low power consumption, compact structure, and easy maintenance and debugging. It is a relatively ideal press. Ball and granulation equipment.

2. The performance of the metal briquetting machine is similar to that of the coal briquetting machine and the desulfurized gypsum briquetting machine. It can press fluorite powder, mineral powder, metal powder, coal powder, coke powder and other materials to make them shape.

3. The metal briquetting machine is forced to squeeze the roller, so the product has the three characteristics of high density, high strength and high hardness, and the press roller of this machine adopts 650mn hard material, which has good wear resistance.

Suppressed material requirements:

1. The particle size of the material is 80-200 mesh.

2. Excessive impurities are not allowed in the material, otherwise the surface of the roller skin will be damaged.

3. The material supply must be satisfied, so that the ball formation rate can be guaranteed. The user needs to be reminded that the wear of the roller skin is severe when the metal is pressed into a ball. The user should pay special attention to the material of the roller skin when purchasing the metal briquetting machine, and it is best to use wear-resistant alloy forging.