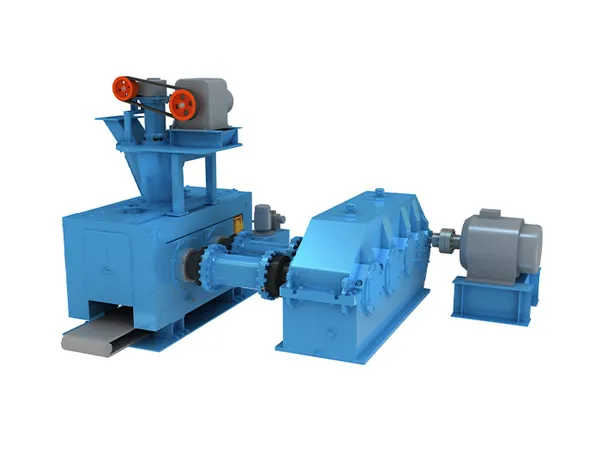

In the field of industrial production, especially for those industries that need to convert powdered materials into pellets with specific shapes and strengths, high-pressure briquetting machines play a vital role. As a key component in the briquetting machine, the design and performance of the pre-pressing screw directly affect the pretreatment effect of the material and the quality of the final pellets. This article will discuss in detail the design points of the pre-pressing screw of the high-pressure briquetting machine, aiming to provide reference and guidance for the technological progress and equipment upgrades of related industries.

Design of pre-pressing screw of high-pressure briquetting machine

1. Driving mode of pre-pressing screw

The driving mode of pre-pressing screw is the core of its design. Usually, the pre-pressing screw is driven by an AC variable frequency reduction motor, which can provide constant torque to ensure that the material is subjected to uniform and stable force during the pre-pressing process. Another advantage of the variable frequency motor is that the speed can be adjusted according to the material characteristics and production requirements, thereby achieving accurate control of the pre-pressure.

2. Material and wear resistance of pre-pressing screw

The material selection of the pre-pressing screw is crucial because it directly affects the service life and maintenance cost of the equipment. Generally speaking, the pre-pressing screw shaft is made of high-strength alloy steel to ensure its stability and durability under high pressure. The spiral blades are coated with wear-resistant materials, such as carbide or ceramic materials, to reduce wear and extend the service life of the equipment.

3. Pitch design of pre-pressing spiral

The pitch design has an important influence on the working efficiency of the pre-pressing spiral and the fluidity of the material. Reasonable pitch design can ensure the continuous flow of materials during the pre-pressing process to avoid blockage and accumulation. The cylindrical variable pitch design is a common choice for pre-pressing spirals, which can provide gradually increasing pressure during the pre-pressing process to adapt to the characteristics of different materials.

4. Sealing performance of pre-pressing spiral

The sealing performance between the pre-pressing spiral and the roller is crucial to maintaining the stability of the internal environment of the briquetting machine. Good sealing can prevent material leakage and the entry of external impurities, thereby protecting the roller and extending the service life of the equipment. The stepped labyrinth seal is a commonly used sealing method, which realizes the effective sealing of the gap between the pre-pressing spiral and the roller through the cooperation of multiple sealing rings.

…

For more detailed information on the design of the high pressure press preloading spiral, please click here: https://www.zymining.com/en/a/news/key-points-for-designing-the-pre-pressing-screw-of-high-pressure-briquetting-machine.html