The most important and critical step in the construction of the marble floor is the polishing and waxing of the floor. When polishing and waxing the marble cement floor, first use a multifunctional brushing machine with a neutral cleaner or waxing agent to clean the floor. Clean, remove the old wax on the ground, make the stone floor free of debris, dust, and stains. Let’s take a look at the marble floor polishing and waxing construction process.

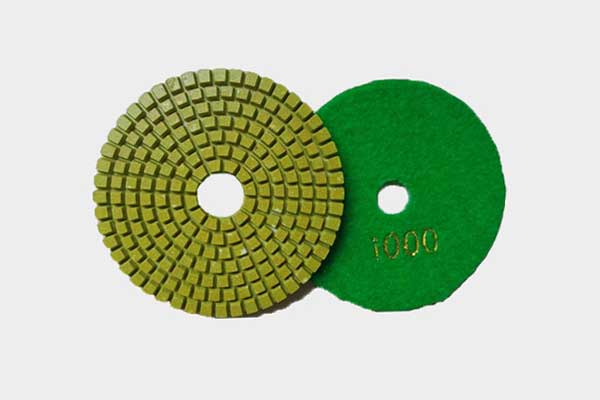

When waxing the stone floor, the floor must be kept dry. First, use a wax mop to evenly coat the back cover and bottom wax on the floor. The bottom wax should be applied in 3 layers, which can be dried by a blow dryer. After the base wax is dried, use wax to drag two layers of high-speed surface wax on the stone floor, and then air-dry the floor. After the wax surface is dried, use a high-speed polishing machine with a marble polishing pad to perform uniform and uniform polishing.

Planing and maintenance of marble floors: waxing and recrystallization

1. Let me talk about waxing first. Waxing and polishing marble is indeed an effective maintenance method, but there are many disadvantages in this kind of marble maintenance.

(1) The wax noodles absorb dust, the ground after treatment is prone to a gray feeling, and pedestrians will leave clear footprints afterwards;

(2) The wax layer closes the pores of the marble, and the moisture inside the marble cannot leak out, causing the marble to appear lesions;

(3) The wax layer has a soft texture and is susceptible to abrasion, which cannot truly meet the requirements of protecting marble.

2. Recrystallization treatment. Recrystallization treatment of marble is a popular marble maintenance method. Marble recrystallization is divided into two parts, one part refers to the machine tool part, the other part is the special chemical material part; the chemical material is also There are two types: one is granite recrystallization, the other is marble recrystallization.

The basic principle of stone crystallization is to combine some special chemical materials with the structure of the marble surface with the help of the heat generated by mechanical friction to produce a new hard crystal layer. Using these stone recrystallization systems to maintain granite and marble can be Make the marble floor get a bright, fresh and natural effect. It can also improve the abrasion resistance of the marble surface and make it more durable.

In general, this kind of maintenance is sufficient for the granite floor once every two years. However, due to the difference in texture of the marble floor, it generally takes about 6 months to do such maintenance, but the specifics also depend on the degree of wear on the marble surface.

Before crystallization, the marble needs to be professionally cleaned in order to ensure the construction effect. Practitioners must establish a scientific and rigorous working attitude.

Cleaning tools and materials:

Tools: floor scrubber, nylon brush plate, water suction machine, mop, bucket.

Material used: weak alkali or neutral detergent.

Operation method:

1. Pour the diluted stone cleaning liquid into the washing machine, move forward from back to front, and walk in a straight line to avoid omissions.

2. Start the water suction machine at the same time of scrubbing, and absorb the sewage while scrubbing. For areas that cannot be washed by the scrubber, you can use mop foam cleaner to wring out and scrub.

3. After cleaning with detergent and soaking up the ground sewage, wash it again with clean water in the same way, and then it can be completed by soaking up the water.

4. Matters needing attention: It is forbidden to use acidic cleaners and powdered cleaners to clean the floor, otherwise it will damage and corrode the marble surface.

5. Standard: clean and translucent, no stains, no marks.

Daily marble maintenance method

Wipe the marble regularly with a slightly damp cloth with a mild detergent, and then dry and polish it with a clean soft cloth. If it is difficult to handle the severely worn marble, it can be polished with steel wool or an electric sander, or wiped carefully with a liquid scrubbing agent. You can choose to use lemon juice or vinegar to clean the stains on the marble surface, but it should be paid special attention that the lemon should not stay for more than 2 minutes. Otherwise, the lemon will be absorbed by the marble and cause new stone pollution. Repeat the operation if necessary.

Then wash and dry. Slight scratches can be protected with a special marble care agent. If it is old or valuable marble, it should be handled by a professional stone maintenance company.

Method of polishing cement floor:

There are generally three ways to polish the cement floor. The cement floor is waxed and the cement floor is transformed into a permeable floor and cement floor crystallization. The construction methods of these three methods are similar, and they can all have a polishing effect and obtain a good cement floor surface treatment effect.

Cement floor polishing and floor waxing

For the new ground with better light collection, you can directly apply the cement floor polishing wax to the ground evenly, and then use a floor polishing machine and a floor polishing pad for polishing. The polishing area should not be too large each time to achieve gloss and no scratches. Only when there are traces can the next area be polished until the waxing and polishing treatment of all the ground is completed. For the old cement floor with wear, dust, pits and cracks, it needs to be ground by a ground grinder. After filling the pits and cracks, waxing and polishing can be carried out. The method is the same as before.

The advantages and disadvantages of waxing and polishing cement floors

Advantages: convenient and quick construction, obvious effect, waterproof and anti-fouling.

Disadvantages: the retention time is not long, the anti-slip effect is not good, and it is easy to get dirty after long-term use.

Transformation of cement floor polishing into permeable floor

The method of transforming cement floor polishing into penetration floor:

For new cement floors with better light collection, you can directly spray the concrete sealing curing agent on the ground, and then use brushes, hairs, etc. to keep the ground moist for about 1 hour, then clean the ground with water, and then polish it. can. For defective old ground, it is necessary to fill in potholes, cracks, control oil pollution, etc., and then do grinding and polishing treatment before spraying concrete sealing curing agent for the next step of construction.

Advantages and disadvantages of cement floor polishing:

Advantages: fast and convenient construction, high hardness, good wear resistance, anti-fouling, and long use time.

Disadvantages: In order to achieve high brightness, it needs to be polished without polishing.

Crystallization treatment of cement floor polishing

The method of crystallization treatment of cement floor polishing: first rough and fine polish the floor with a floor grinder, and then polish the floor. After the floor has a certain luster, dry the floor. Spray the ground crystallizer on the ground of 1 square meter, and use a crystallizer with steel wool and scouring pad to do left and right grinding treatments, until a uniform high-gloss ground appears before moving to the next area. Cycle in this way until the construction area used. Corresponding repairs are required for defective old cement floors.

Advantages and disadvantages of crystallization treatment of cement floor polishing:

Advantages: high surface hardness, good gloss, anti-fouling, waterproof and abrasion resistance.

Disadvantages: long construction time and need to be polished.

The above is the relevant introduction about the marble floor polishing and waxing construction technology. I believe you will have a simple understanding of this after reading it. If you need it, you can continue to pay attention to us.