As more and more stone is applied to the decoration project and enters people’s daily life and work, people put forward higher requirements for the decorative effect of the stone. “Stone needs nursing” is increasingly accepted by people, and stone conservation has become an important part of the process of building decorative stone.

First, marble polishing pad renovation

Renovation of marble polishing pad is to renovate the marble floor, wall (or exterior wall), countertop, column and other marble plates without any seams, pollution, weathering, holes, no light, etc. Nursing machines, tools, etc. are cleaned, polished, and polished to restore the same luminosity as before the initial installation and to make the marble surface more visible.

The refurbished marble polishing pad has the following four effects:

1. Increased hardness: After treatment, the surface is not dusty, wear-resistant and scratch-resistant, and prolongs the service life of the stone floor.

2, mirror effect: the surface of the terrazzo can reach the same luster of natural stone, and the finish is high. The luminosity can reach 105°.

3, good anti-fouling: corrosion resistance, oil, water, anti-seepage, anti-fouling, water absorption is less than 0.5%.

4, easy maintenance: daily cleaning, maintenance is easy, greatly reducing the cost of cleaning and maintenance in the later period, daily use only dust push with electrostatic vacuum dust, regular neutral detergent cleaning or stone care solution polishing marble board.

Second, the marble polishing pad renovation step procedure

Natural marble, also known as marble, is mainly composed of calcium carbonate and magnesium, sodium, silicon, etc. The hardness of the friction type is about 4 or 5, which is soft. It is less resistant to weathering, so it is easy to lose luster on the worn surface. We can choose to carry out light, medium and deep stone renovation according to the degree of stone surface wear.

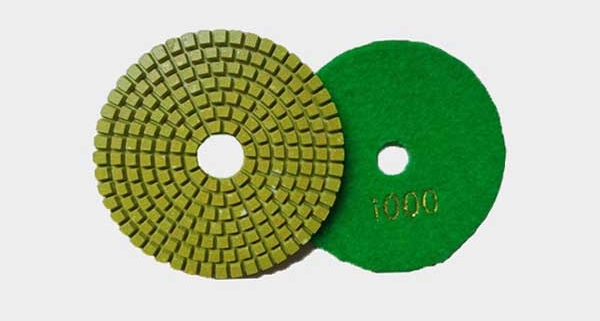

The equipment, accessories and consumables required for marble renovation are: ordinary weighting machine, 4 inch diamond water-grinding disc, 17-inch refurbished disc, water absorbing machine, signboard, watering can, glass scraping, water wiper and bucket.

1. Marble polishing pad is lightly refurbished

The surface of the stone is slightly scratched and can be refurbished with a mild refurbishment process. If there is old wax on the ground, first wax, then use 800# diamond water grinding disc and clean water for 10 minutes. Note: add water in the grinding process to keep the ground moist, and use suction machine to absorb the sewage to prevent the second pollution of sewage. ground. Then change 1500#, 3000# polished sheet, diamond water-grinding sheet, and polish one by one by the above method. After the refurbishment process is completed, the water on the surface of the stone is washed with water and the surface of the stone is gently refurbished.

2. Marble polishing pad moderately refurbished

When the surface of the stone loses its luster, it can not reflect the object at all, but it has no deep scratches. It can be refurbished by a medium refurbishment process. Polished pieces of 200#, 400#, 800#, 1500#, 3000# and diamond water-grinding pieces were polished one by one. The grinding method and precautions were consistent with the above.

3. Marble polishing pad depth renovation

When the surface of the stone is holed, weathered, severely corroded, completely tarnished and deeply scratched, it can be refurbished by a deep refurbishment process. Before renovating, the holes should be repaired as follows: first clean the dirt in the holes, then dry the stone, and use imported epoxy resin or unsaturated resin glue according to the color and reflective characteristics of the original stone. After the coloring, the repair was carried out, and the weighting machine, the new plate and the 50#, 150#, 200#, 400#, 800#, 1500#, 3000# polished diamond water-milling pieces were used for one-by-one polishing. The grinding method and precautions are consistent with the mild renovation.

If marble crystal hard powder is used for hard treatment of stone crystal, in the process of refurbishing, after grinding with 800# diamond water grinding sheet, the crystal hard powder can be directly used for crystal hard treatment, and the surface of the treated stone is as bright as new.