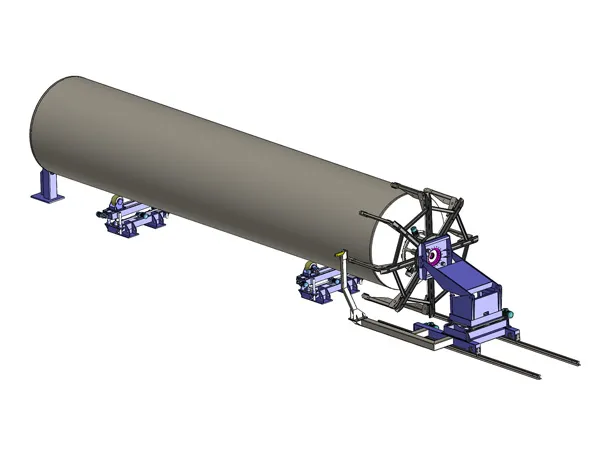

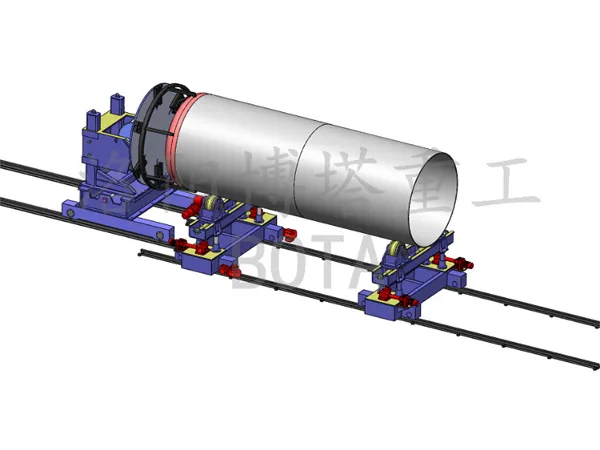

A storage tank welding production line is a specialized setup designed for the efficient manufacturing of storage tanks used in various industries, such as oil and gas, chemicals, water treatment, and food processing.

Key Components of Storage Tank Welding Production Line

Raw Material Preparation:

Sheets of steel or other materials are cut to size and prepared for welding.

Welding Stations:

Automated or semi-automated welding machines perform various types of welding (e.g., TIG, MIG, or submerged arc) to join tank components.

Assembly Line:

Components are assembled in a sequential manner to streamline production.

Inspection Stations:

Quality control measures, including visual inspection and non-destructive testing, ensure weld integrity and overall quality.

Finishing Area:

Tanks are finished through processes such as grinding, painting, or coating to enhance durability and corrosion resistance.

Storage and Logistics:

Finished tanks are stored or transported for installation or further processing.

Storage Tank Welding Production Line Production Process

Design and Planning:

Detailed plans are developed, often using CAD software, to specify dimensions and material requirements.

…

For more detailed information about the process flow of the tank welding production line, please click here: https://www.bota-weld.com/en/a/news/storage-tank-welding-production-line-process.html